立兴复合材料,致力于绝缘,散热,耐温,压合,防火,背光等不同特性的各种环保硅胶产品,主要生产各种规格之硅胶绝缘散热片/布,PCB热压缓冲垫片,发热板用热压合硅胶材料,导电材料,EMI,背光硅胶材料,硅胶套管,导热软性硅胶,硅胶密封材料

全国咨询热线:

13926908508 黄先生

新闻资讯

新闻资讯 新闻动态

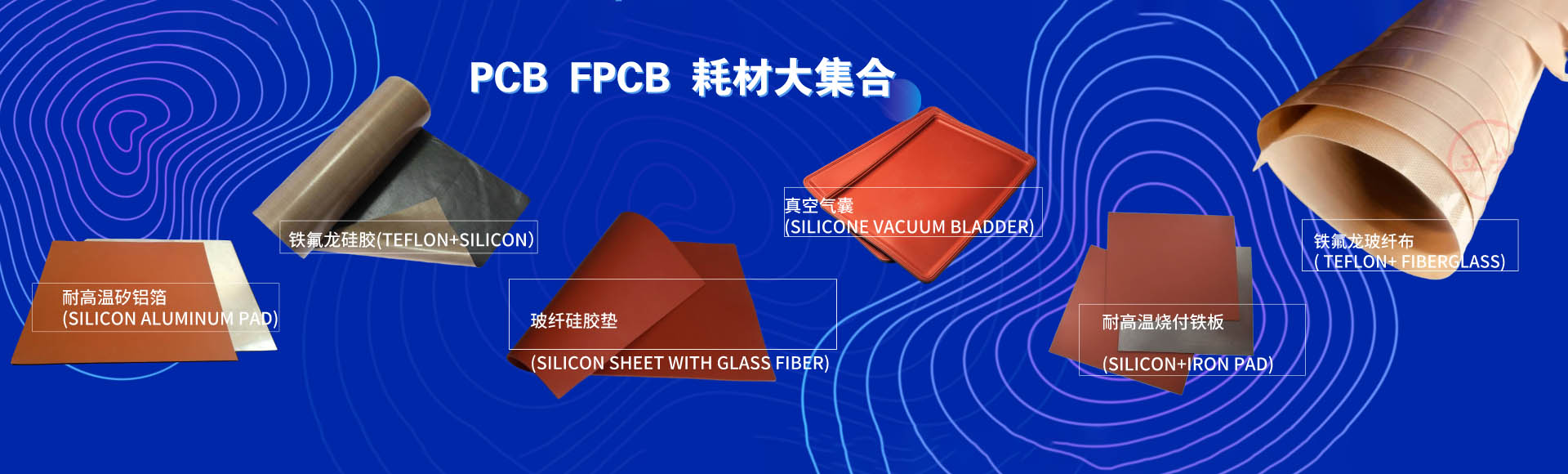

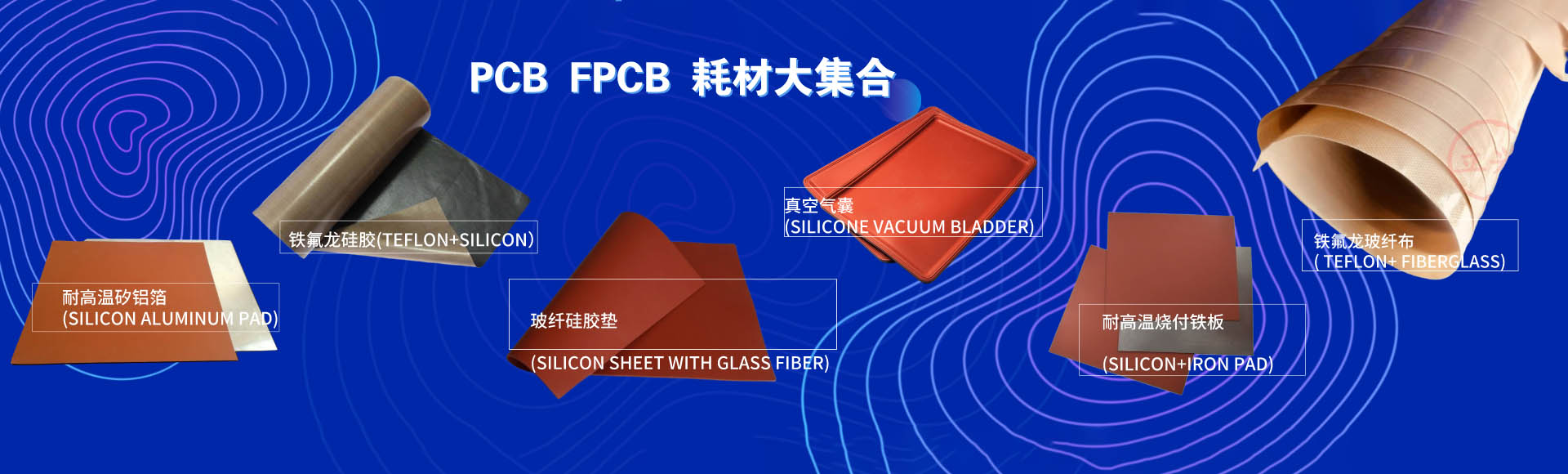

新闻动态FPC快压机(Fast Pressing Machine)是用于快速压合柔性印制电路板(FPC)的设备,其压合过程需要使用一些耗材。以下是常见的FPC快压机压合耗材:

1.烧付铁板:烧付铁板,也称为热板或加热平板,用于在压合过程中施加热量和压力。它有助于FPC层间的粘合和固化。

2.硅铝箔:硅铝箔是一种耐热材料,具有良好的导热性能。可放置在FPC层间,改善热量传递,并确保在压合过程中温度均匀分布。

3.绿硅胶:绿硅胶,也称为硅橡胶,是一种柔软且耐热的材料,用于绝缘和保护。在FPC压合过程中,可以作为保护层或封装材料使用。

4.铁氟龙玻璃纤维布:铁氟龙玻璃纤维布,通常称为铁氟龙布,是一种非粘性和耐热的材料。常用作FPC与压合设备之间的脱模剂或防粘层,以防止粘连,并确保压合后的顺利脱模。

这些附加材料,如烧付铁板、硅铝箔、绿硅胶和铁氟龙玻璃纤维布,对于FPC的快速压合过程起到了重要作用,提供了必要的热传导、绝缘、保护和脱模特性。具体选择和使用这些材料取决于FPC压合过程的要求和期望的结果。

there are a few more materials commonly used in the FPC fast pressing process:

1. Soldering Plate: A soldering plate, also known as a hot plate or heated platen, is used to apply heat and pressure during the pressing process. It helps in the bonding and consolidation of the FPC layers.

2. Aluminum-Silicon Foil: Aluminum-silicon foil is a heat-resistant material used for its thermal conductivity properties. It can be placed between layers of the FPC to improve heat transfer and ensure uniform temperature distribution during the pressing process.

3. Green Silicone Gel: Green silicone gel, or silicone rubber, is a flexible and heat-resistant material used for insulation and protection purposes. It can be applied as a protective layer or encapsulation material during the FPC pressing process.

4. PTFE-Coated Fiberglass Cloth: PTFE-coated fiberglass cloth, commonly known as Teflon-coated fiberglass cloth, is a non-stick and heat-resistant material. It is often used as a release agent or non-stick layer between the FPC and pressing equipment to prevent sticking and ensure smooth release after pressing.

These additional materials, such as the soldering plate, aluminum-silicon foil, green silicone gel, and PTFE-coated fiberglass cloth, contribute to the efficient and effective pressing of FPCs, providing necessary heat transfer, insulation, protection, and release properties. The specific selection and usage of these materials depend on the requirements of the FPC pressing process and the desired outcomes.